Code Compliance Issues

To maintain required fire resistance ratings, building code compliance now requires the annual inspection and repair of all exposed sprayed fireproofing in buildings. To restore the code required fire resistance ratings patching compounds MUST have been fire tested with the specific fireproofing product being repaired. Patching with compounds that have not been specifically “approved” for repair of the damaged sprayed fireproofing do not restore the code required fire resistance rating.

Today manufacturers of the major brands of sprayed fireproofing, market patching products that have been evaluated WITH their sprayed fireproofing by Underwriters Laboratories® Inc. Underwriters Laboratories® Inc. has evaluated these patching products have determined that the use of these specific products to patch damaged fireproofing will maintain the fire resistance ratings of the in place sprayed fire proofing products. To maintain the fire resistance ratings ONLY products tested and approved for use with the specific in place sprayed fireproofing may be used. There is no single product that can be used to generically patch “all” in place fireproofing products.

The first step is to determine what in place product exists in the building. Once the product has been determined it is important to source the patching product from the manufacturer of the in place fireproofing. Since the early 1970?s it is estimated that GCP Applied Technologies sprayed fireproofing products, Monokote® (MK-4, MK-5, and MK-6) have been applied to more than 50% of all structural steel buildings in the United States and Canada. Monokote® Patching compound, produced by GCP Applied Technologies has been evaluated and approved by Underwriters Laboratories specifically for patching these products. Monokote patching compound is now available as a convenient “mix in the bucket” package that can be easily ordered in one or more bucket quantities for shipment anywhere in the United States and Canada.

MONOKOTE® Patching Compound

Fireproofing Patching Material for Repairing Monokote MK-5, MK-6 and MK-10 Products

Description

Monokote® Patching Compound is the only UL approved patching material for patching Monokote MK-5, MK-6 and MK-10 products that when applied as directed, will maintain the original fire rating of the steel membe . It has been developed by GCP Applied Technologies to meet specialty, commercial and industrial fireproofing patching requirements. Monokote® Patching Compound is a mill-mixed plaster, (cementitious) fireproofing material that can be hand mixed and trowel applied as required for patching and repairs to surfaces. Monokote® Patch Compound is hand-applied directly to the steel and/or well-bonded material using standard plastering tools and techniques. It has excellent bonding characteristics; it can be applied up to one inch per pass. Monokote® Patching Compound is classified for use in all UL designs associated with Monokote MK-5, MK-6 and MK-10 products. References to Monokote® Patching Compound can be found at Database.UL.com by searching for UL File number R4339. Per UL patching guidelines, Monokote® Patching Compound can only be used to patch individual areas of 144 square inches or less. It will provide the same hourly fire resistance of the material being replaced as long as the thickness of the Monokote® Patching Compound is equivalent to or greater than the required thickness of the material being replaced.

Features & Benefits

Monokote® Patching Compound offers the following advantages to applicators:

- UL Classified – Monokote® Patching Compound is the only UL approved patching material for patching Monokote MK-5, MK-6 and MK-10 products that will maintain the original fire rating of the steel member.

- Convenient – Conveniently packaged in 5 gallon pail. Mix in 1.5 gallons of water and begin patching.

- Easy to Mix – Simply add water and mix with a handheld drill mixer.

- Easy to Apply – Apply using a trowel. No spray equipment is needed.

- Excellent Bond Characteristics – Up to one inch thickness per pass

Uses

Monokote® Patching Compound is ideal for patching damages resulting from typical jobsite installation or reno¬vation activities:

- Duct hangers

- Electrical pipes

- Drywall

- Sprinklers

- Heating

- Ventilation

As IBC requirements for increased SFRM inspections for occupied buildings are implemented, Monokote® Patch¬ing Compound will be an ideal product for maintenance repairs.

Delivery & Storage

- All material to be used for fireproofing should be delivered in original unopened pails bearing the name of the manufacturer, the brand and proper Underwriters Laboratories Inc. labels for fire hazard and fire resistance classifications.

- The material should be kept unopened until ready for use.

Surface Preparation

- Surfaces to which fireproofing is applied must be thoroughly cleaned of all foreign material which might impair adhesion. All loose material, including dirt, loose rust, mill scale and any other foreign material, that would impair adhesion of the patching material must be removed prior to patching. Where damaged material extends to the steel or concrete substrate, removal should be to the steel or concrete substrate.

- Where well-bonded material exists below the damaged material, removal of the damaged material should extend to the well-bonded firm material. There is no requirement to remove well-bonded material that lies immediately beneath loosely bonded or poorly adhered material.

- The patching material is keyed into the material surrounding the patch. It should be understood that the integrity of the surrounding material shall not have been impaired. If the surrounding material has been damaged it should be removed prior to patching.

- When applying new material over in place mate¬rial that has dried, it may be necessary to dampen or pre-wet the in place material sufficiently to prevent premature drying of the newly applied patching material.

Mixing

- Monokote Patching Compound should be mechanically mixed. Hand-held mixers such as a drill mounted mixer are suitable.

- Add 1.5 gallons of potable water to the pail of Monokote® Patching Compound Mixture.

- Mix for 1-3 minutes until the mix is a lump-free, cohesive uniform slurry. All material is to be thoroughly wet.

- When properly mixed, Monokote® Patch Compound has a potlife between 2 to 4 hours.

Application

- Monokote® Patching Compound is hand-applied directly to the steel and/or well-bonded material using standard plastering tools and techniques. An individ¬ual patched area should not exceed 144 square inches.

- Maximum 1 inch thickness can be applied in a single pass. Anything above 1 inch requires multiple coats. Allow material to become stiff but not completely dry before applying the next coat.

- When patching over in-place material that has dried, immediately before application it may be necessary to pre-wet the in-place material sufficiently to prevent premature drying of the newly applied patching mate¬rial.

- One pail of Monokote® Patching Compound can cover 6.5 sq ft of area at a thickness of one inch.

- Monokote® Patching Compound should not be used if it contains partially set, frozen or caked material.

- Monokote® Patching Compound should not be retempered if the material has started to stiffen or set.

Environment

An air and substrate temperature of 40°F (4.5°C) minimum should be maintained for 8 hours prior to application, during application and 24 hours after application of Monokote® Patching Compound.

Provide ventilation to achieve a minimum fresh air exchange rate of 4 times per hour until the material is substantially dry

Safety

A Material Safety Data Sheet for Monokote® Patching Compound is available on our web site at www.gcpat.com or call toll free at 866-333-3SBM.

Download Product Datasheet PDF

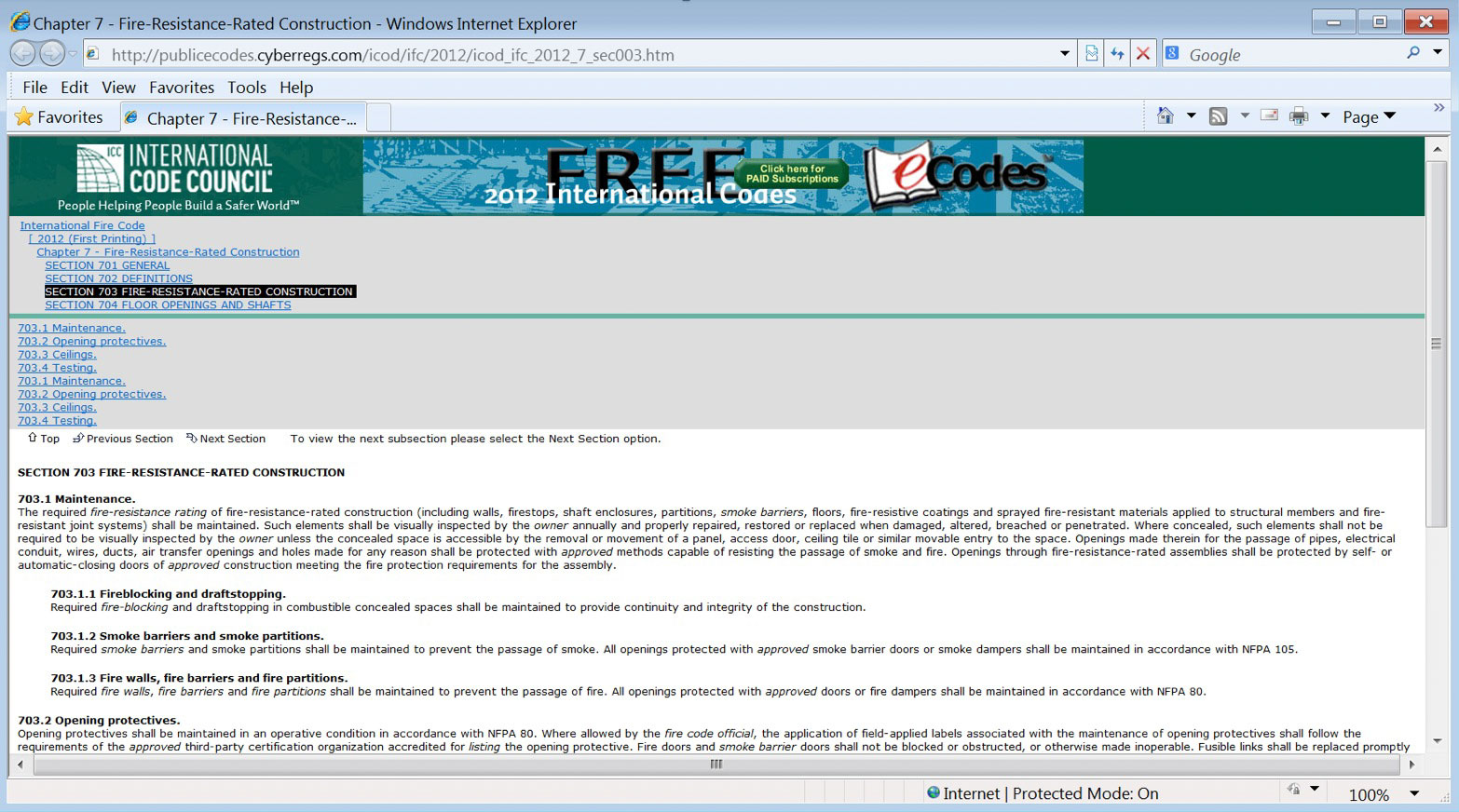

Documentation of Code Requirement for Inspection and Repair:

International Building Code documentation requiring the inspection and repair of fire resistant construction (patching of sprayed fireproofing) as to “maintain the fire resistance rating.”

http://publicecodes.cyberregs.com/icod/ifc/2012/icod_ifc_2012_7_sec003.htm

Documentation and listings of Monokote Patching Compound with GCP Applied Technologies Monokote products

Maintaining the fire resistance rating is only accomplished when the patching product has been tested and evaluated WITH THE SPECIFIC IN PLACE FIRESISTIVE MATERIAL. Testing of a patching material alone or with unrelated materials DOES NOT maintain the fire resistance rating.

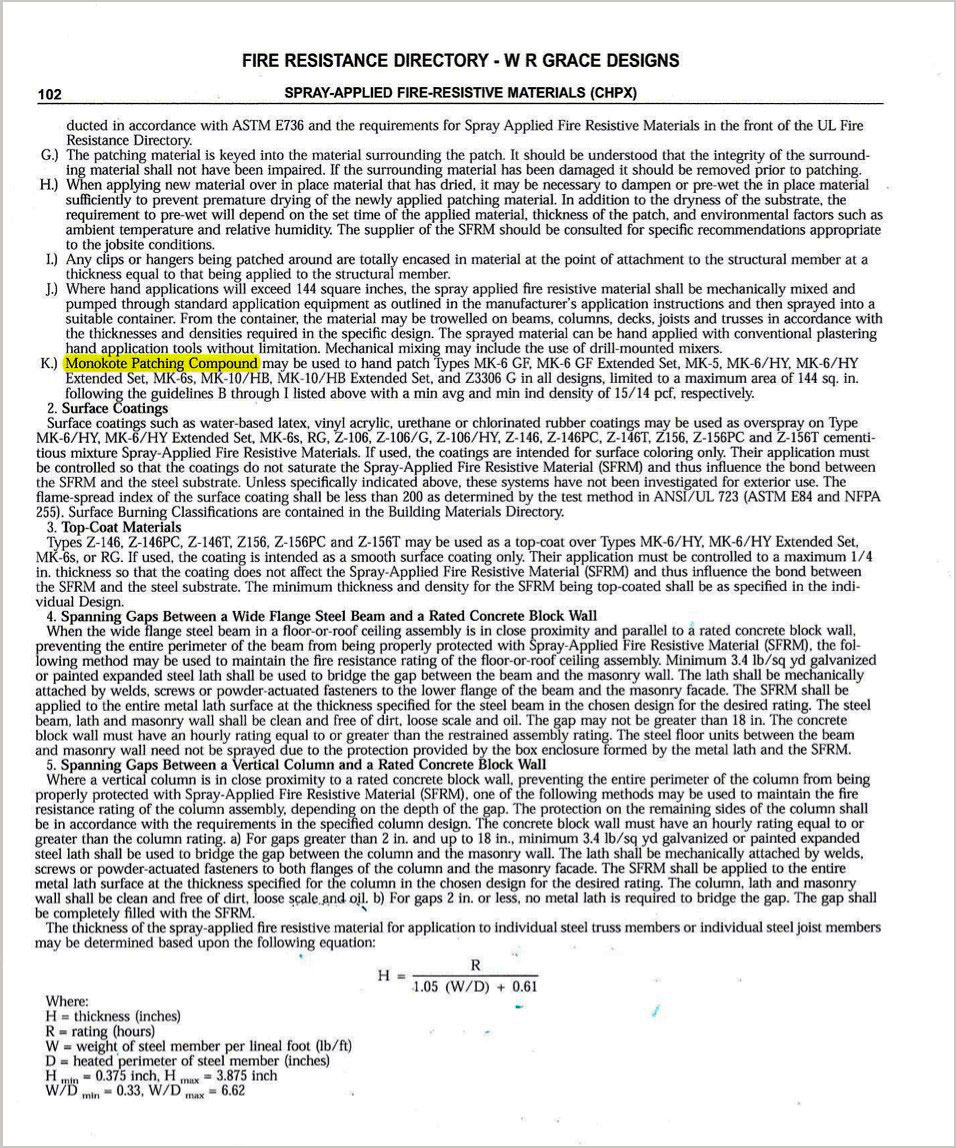

GCP Applied Technologies listings in the Underwriters Laboratories Fire Resistance Directory (UL book). Page 102 specifically details compatibility of Monokote Patching Compound as evaluated as acceptable for repair of Monokote products to maintain the fire resistance ratings of protected assemblies.